If there’s an unsung hero on the sneaker, it’s the insole. It is perhaps the least sexy part of any given footwear design, hidden on the innards and unable to reach the same levels of visibility as the upper or outsole, but it’s the first one you feel as you step your feet into a pair. The layer of cushioning that sits just underneath the foot—also known as a sockliner—is a component rarely mentioned in the detailed tech sheets that brands put out accompanying new shoes, and not even the most sneaker-obsessed discuss it with any regularity. How can companies make this piece of cushioning less boring?

“We need to look at ourselves not like, ‘Oh, we sell sockliners,’” 31-year Nike veteran Skip Lei tells Sole Collector. “We’re like the creamy nougat center of that candy bar. We’re the very best part, man. We’re the part that you can’t wait to get to.” Lei now works for Ortholite, an insole company that supplies brands like Nike, Adidas, New Balance, Asics, Under Armour, and Puma with 500 million new pairs every year.

Lei scored a job at Nike right out of college in 1981 after sending the brand his résumé, starting out as a Foot Locker field service rep and eventually moving into an EKIN role. He went on to hold a myriad of positions at the Swoosh, helping revamp its tennis category in the late 1980s and establishing programs like Special Make Ups, which gave unique shoes to retailers to help their bottom lines, and Quickstrike, originally developed to react to industry trends.

After leaving the company in 2013 (Nike co-founder Phil Knight showed up for his going-away party) and taking a few years off from the footwear industry, Lei was pulled back in at the behest of Ortholite, which hired him as its VP of innovation and strategic partnerships in February, 2017. Two of his major tasks with the brand are bringing new tech to market and making people actually care about it.

The irony is that wide swaths of the sneaker-consuming public are already acquainted with (if not familiar with) Ortholite. The company has had a relationship with Nike since 1997, and its products are in many Swoosh models currently on shelves; the latest Air Jordans use Ortholite insoles. But sneakers using these sockliners aren’t co-branded usually, so there’s no mention of the brand in product descriptions. What’s more, the vast majority of its business is as a supplier—Ortholite has just one after-market product available, otherwise consumers have to get its insoles by buying sneakers from the big brands.

Lei is drawing from the learnings of his long tenure at Nike to try to increase awareness around Ortholite. As he sees it, letting people actually see the tech underneath their feet will help the brand drive conversation.

“You buy a car, you want to look under the hood,” Lei explains. “You don’t know what the hell’s in there, you can’t tell shit what’s inside the hood but you look—you feel like you’re supposed to...it creates an immediate engagement by having that visual technology, that reference, that ‘Ah, I wonder what that feels like.’”

It’s a very Nike way of thinking, and one that’s worked for the brand for decades. The Nike technology and materials that are most salient beyond sneakerhead circles are those that are visually evident—Air Max is something that anyone can see and understand, which has contributed to Nike continually using the cushioning for 30 years now. Similarly, Flyknit doesn’t need much explaining; the name and one look at the material are enough. Even Adidas’ most important innovation win this decade, its Boost cushioning developed by BASF, relies heavily on the brand finally having a tech that’s easily communicated visually.

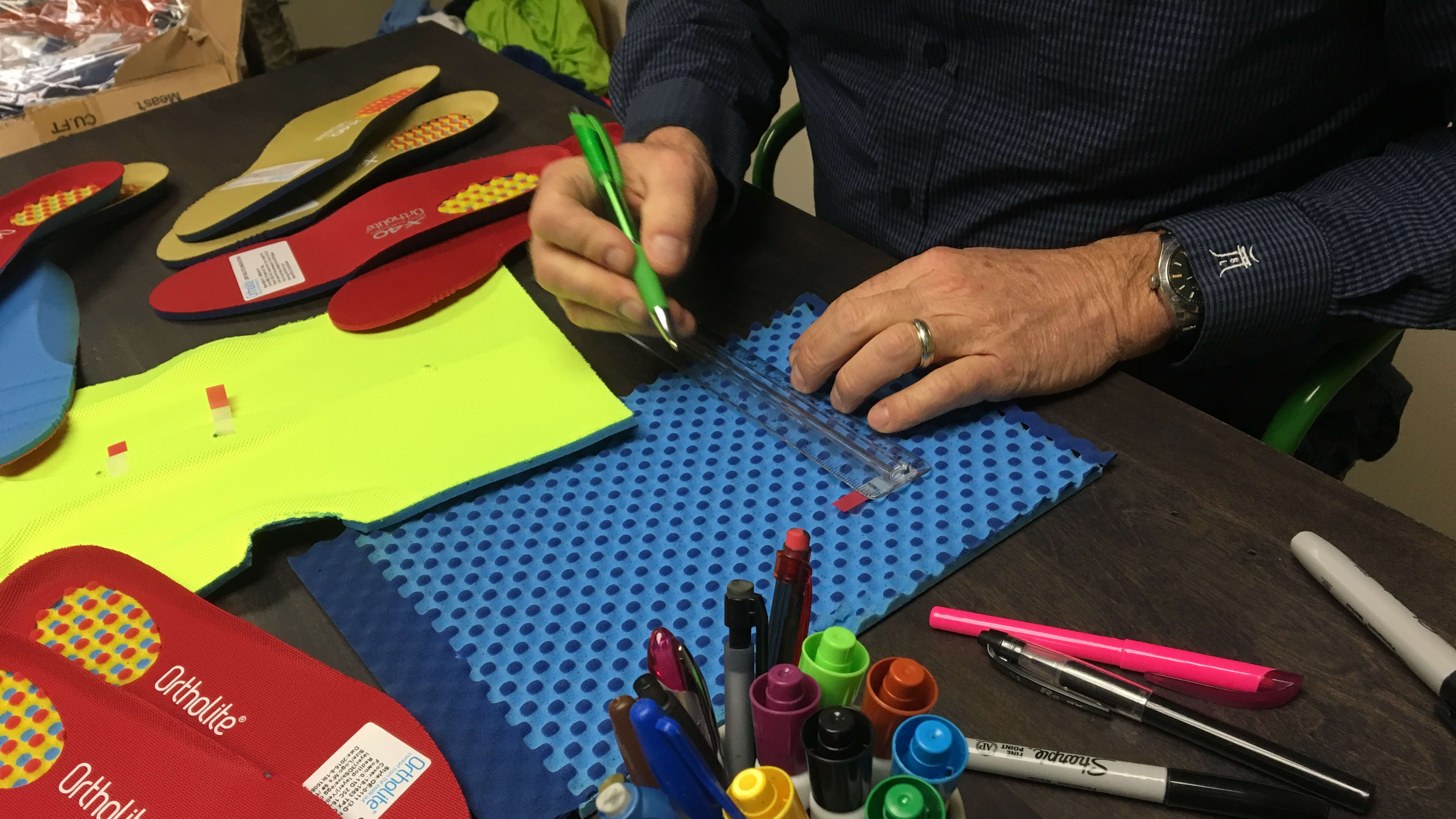

This method of showing shoppers what their shoes are made of can already be seen in upcoming Ortholite products. The best example of this is the 3D Skive Heel, a sockliner that has a section in the heel marked off with a wavy foam pattern. The placement is particularly important for visibility, as a top-down look at a shoe usually has the heel as the only uncovered part. Ortholite has also released the Super Sipe insole, which caters to the industry trend of flexible footwear with slits on bottom that allow it to act something like Nike’s Free outsoles.

The tendency to treat insoles as an afterthought exists all the way down at the product development level—according to Lei, product line managers at Nike will often use cheaper insoles to shave prices off the final cost of a shoe for the sake of margins.

“If there’s price pressure it’s one of the easiest things to take out. They can’t change the tooling, they may not be able to change all these upper materials—some of these decisions would require a lot of changes, but they can pull that bad boy out and replace it with something that would be lower cost. It’s the simplest financial fix to increasing your margin.”

Is there a ceiling to what Ortholite can do branding-wise despite its, and Lei’s, high aspirations? The product will always be stuck inside sneakers, and it’s unlikely that consumers will associate insoles with designers or athletes in the way that they do full-on shoes. But, the introduction of visible tech could conceivably make Ortholite more known among laypeople, and the company has innovation summits and a team of 100 in Asia working on chemical formulas for insoles. For his part, the Nike vet sees the possibilities as limitless.

“I wanna make the insole an incredibly important part of the shoe,” Lei says. “It’s gonna be cool and it’s what people want. Nike—let’s face it, athletic footwear was just athletic footwear—Nike created the vibe and the demand for athletic footwear. It takes a long time but, hey, I think components can do it too.”