Inscribed in big bold letters on the walls inside of Under Armour’s Lighthouse facility is the Albert Einstein quote, “The significant problems we have cannot be solved at the same level of thinking with which we created them.”

The maxim, along with others adorning the inside of the space in Port Covington, Maryland coined by the company’s founder and CEO Kevin Plank, are the basis behind the space’s goal: to change the way the sportswear industry brings designs to fruition.

“This is really going to enable us to be closer to the process so that we can make better products,” said Kevin Haley, Under Armour’s president for product and innovation. “You do this by partnering with people who are the best in the world at whatever they do.”

Walking into the Lighthouse is something like getting to visit Area 51 or some other high-tech, top-secret government agency. You’re welcomed by two black glass doors that slide open to reveal technicians in white lab coats, state-of-the-art manufacturing equipment, and curtains that guard upcoming product from being leaked to the public.

The idea behind the space is to bring production closer to home and to give UA designers new tools to work with when making products. Instead of spending weeks traveling to Asia and months waiting for samples to return, designers can simply make the 10-minute drive from UA’s main headquarters in Baltimore and get back a sample within a day, if not hours.

“Now we have the ability to put the designers, developers, and the engineers in a space that allows them to work directly with these new manufacturing processes,” Haley said. “It’s just a different way of looking at things that will ultimately allow us to make shoes with more precision, less variance, and then ultimately make it local for local.”

Eventually the goal is for Under Armour to create products locally for the markets which they serve. Although the Lighthouse is a step closer to that goal, it's ultimately still a long way ahead.

The space isn’t built for mass production as of right now. Think of it more as UA’s version of a mad scientist laboratory where they can make small runs of experimental product before wider distribution.

It also acts as a space to create player exclusive items. Just before Under Armour opened up the Lighthouse’s black tinted doors to us this month, technicians were producing a limited run of 300 compression tights for Stephen Curry.

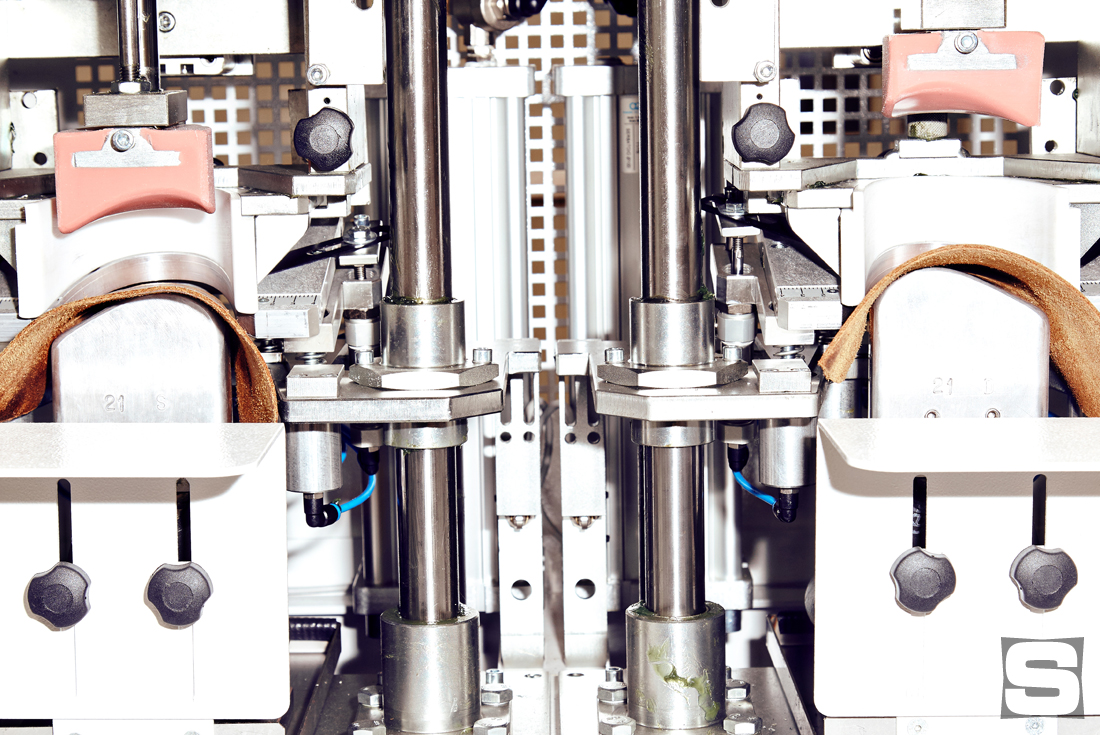

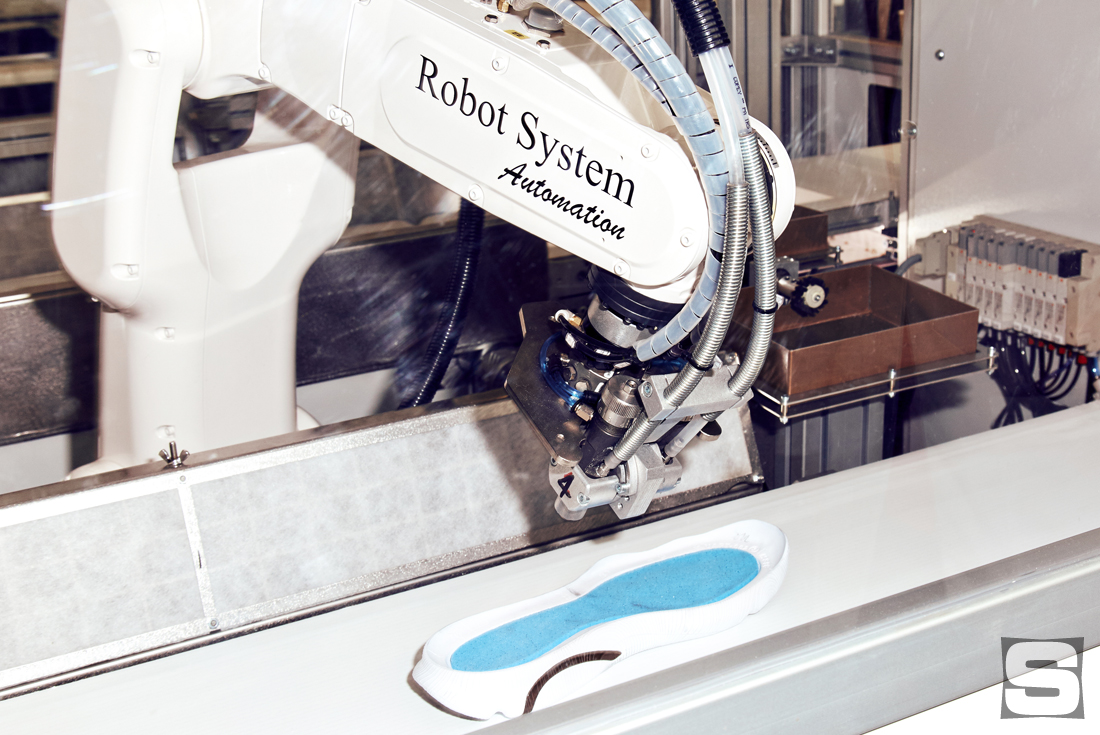

A bulk of the production inside the Lighthouse is automated, which significantly cuts down on the manpower and mistakes in production that result from human error. “Sometimes 200 people will touch each shoe as it moves down the assembly line,” Haley said. “Every step along the way a human hand touches a product and there’s a few millimeters of variance and chance for product issues.”

Not only will Under Armour’s U.S. design team have access to the Lighthouse’s high-tech machinery, which also includes a body scanner that gathers the exact metrics of an athlete’s body movements and 3D printing equipment, they’ll also be able to share ideas with companies outside of the sportswear industry.

The Lighthouse is located at City Garage, a 140,000-square-foot former bus depot turned innovation hub that's owned by Plank and is home to his other business ventures. The new design hub makes up a third of the space at City Garage. Haley says being yoked together with designers and manufacturers from other industries can only help foster new ideas for Under Armour.

“We’re surrounded by people who are like minded and running into a lot of different technologies out there,” he said. “It inspires us to have a different way of looking at shoe construction or apparel construction and that’s really what Lighthouse is: a place to house that type of forward thinking.”